Perhaps the most reliable of the conformal coatings, parylene (para-xylylene di-iodide) is also one of the more expensive coating options.

Factors & Considerations

Parylene is often priced out to be one of the more expensive conformal coating options. After a quick look at some of the cost factors, it will be easy to see why. Three of the main factors that influence parylene cost are raw materials, labor, and lot volume.

Raw Materials – Parylene Dimer and Adhesion Promotion

Parylene dimer is the raw form of parylene. It is the solid inserted into the machine that is broken down through the deposition process. Cost for parylene dimer can be anywhere from $200 to $5,000 per pound depending on the different type of dimer. A typical coating run is around a pound of dimer.

Different adhesion promotion methods require different raw materials. From various board cleaning solutions to A-174 silane, these raw material costs need to be added to the price per assembly. There is not much that can be done with these costs, as adhesion is the name of the game in parylene.

Parylene Labor Costs

Like all conformal coatings, masking is usually the most labor intensive part of the process. However, parylene is different from other conformal coatings in that it is applied in a gaseous state through a vapor deposition process. The parylene molecules will penetrate anywhere that air can. As a result, great care needs to be taken during the masking process to ensure that every connector is adequately sealed and all tape is firmly pressed against the coating keep-out areas.

Another factor that will result in increased labor costs is the increased time spent per board to increase parylene adhesion. Spending extra time cleaning products and applying different adhesion promotion mediums will result in increased labor times.

Parylene Lot Volumes

Items to be parylene coated are placed into a vacuum chamber. There is finite space available in the chamber and everything inside gets coated. In order to get the lowest cost, we have to maximize the products in the chamber. If we are able to divide the material costs among a greater number of boards, the cost per board drastically drops.

Determinin Factors

Everyone loves the barrier properties of parylene. The resistance to solvents and moisture, incredible dielectric strength, and the completely uniform coverage are enough to make any engineer squeal with delight. The question that immediately follows is, "How much does parylene cost?"

There are a couple different factors that go into decided parylene cost. One of these factors is the material cost. Parylene dimer can be anywhere from $100 to $10,000+ per pound depending on the type and quality. Other raw materials, such as the cleaning materials and adhesion promotion mediums, also factor into the materials costs for parylene.

Another large factor that goes into parylene cost is the size and quantity of the objects to be parylene coated. The objects get placed into a chamber during the parylene process for coating. Since the machine has fixed costs to operate, by maximizing the number of objects in the chamber will spread these fixed costs out, lowering the price per unit drastically.

By far, the largest factor in determining how much parylene will cost you is the amount of human intervention that is required. Human intervention is the amount of time that will be required for our operators to properly apply adhesion promotion, mask, de-mask, and inspect the products prior to completion. Obviously with labor rates being so high, greater amounts of direct labor required will result in much higher prices.

As you can see, many different factors go into deciding how much parylene costs. If the product is small and requires no masking, the price per could be very cheap, even less than a penny. If the product demands all of the chamber space and takes eight hours to mask, then expect a very hefty bill when your product returns.

The Process Explained

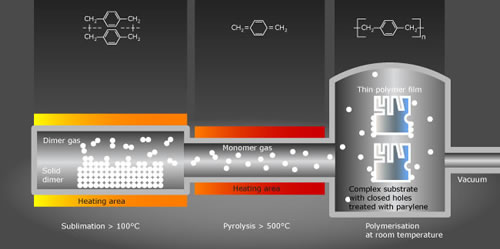

Parylene coating is applied through a vapor deposition process onto the substrate or material that is being coated. Depending on the coating type and required thickness, typical parylene deposition rates are about .2/mils per hour, so machine runs can vary from as little as 1 hour to over 24 hours. The process begins with raw dimer in solid state (these are: Parylene C, Parylene N, Parylene D, Parylene AF-4, or other variants) being placed into a loading boat, which is then inserted into the vaporizer. The raw dimer is heated between 100-150º C. At this time, the vapor is pulled, under vacuum into the furnace and heated to very high temperatures which allows for sublimation and the splitting of the molecule into a monomer. The monomer gas continues to be drawn by vacuum one molecule at a time onto the desired substrate at ambient temperatures in the coating chamber. The final stage of the parylene deposition process is the cold trap. The cold trap is cooled to between -90º and -120º C and is responsible for removing all residual parylene materials pulled through the coating chamber.

The process is visually described through figure 1 below:

The parylene deposition process is relatively simple to understand, but tough to master. A thorough understanding of the process is key to controlling thickness and ensuring a successful coating cycle.

Qualifications to Consider

Materially, parylene is the most distinctive of the major conformal coatings. But just how does it differ from liquid coatings -- acrylic, epoxy, silicone and urethane??

Liquid coatings are just that, wet; they begin as liquid and are applied to substrates in that format, by brushing, dipping or spraying the fluid material onto the substrate.

A common generic name for Poly-para-xylylene, parylene forms a protective plastic film when applied to substrate surfaces, through a chemical vapor deposition (CVD) process. In contrast to liquid coatings, parylene begins in a solid format, as a white powdered dimer, requiring specialized equipment to enact CVD in a vacuum. Transformed to a gas, the parylene is applied as uniform, pinhole-free conformal coating to targeted substrate surfaces.

A green polymer chemistry without the need for catalyst or solvent, parylene requires neither an initiator nor termination group. Commonly used precursors include paracyclophane, paraxylylene and di-paraxylylene. During CVD:

The CVD process is far more complex than the general brushing, dipping and spraying procedures used for wet coatings. The result is a range of conformal films without peer or functional versatility. Parylene films are very adaptable, protecting substrates with a wide range of advantages, compared to liquid coatings. Chemically inert parylene provides:

Where to Buy Parylene

When purchasing parylene it is important to use a qualified vendor like Diamond MT (DMT), whose in-depth understanding of the CVD process accurately controls film coverage and thickness, ensuring a successful coating cycle. Based on our experience and expertise, we recommend you use these criteria when evaluating vendors for parylene conformal coating:

DMT is well-positioned to satisfy clients standardized or custom-designed parylene or liquid conformal coating projects. As necessary, we can quickly develop a custom solution, ensuring your specialized conformal coating requirements are expertly achieved. Fifteen-plus years’ experience with multiple mediums further supports our ability to handle any unexpected developments that might arise during the coating process. You’ll be assured the essential degree of parylene or liquid conformal coating attention and proficiency your project needs.