In addition to cracking, a range of associated issues may interfere with successful coating of parylene films. Because it is applied via CVD, parylene generates a structurally continuous film covering a PCB or similar assembly. In CVD, the interaction of vapor-phase chemical reactants formulate a non-volatile solid film on a substrate, useful for a variety of applications like corrosion resistance, erosion defense, and high temperature protection.

Issues that Complicate Parylene Coating

In addition to cracking, a range of associated issues may interfere with successful coating of parylene films. Because it is applied via CVD, parylene generates a structurally continuous film covering a PCB or similar assembly. In CVD, the interaction of vapor-phase chemical reactants formulate a non-volatile solid film on a substrate, useful for a variety of applications like corrosion resistance, erosion defense, and high temperature protection.

Thus, in contrast to competing wet coating processes, parylene exhibits no liquid problems like capillary flow or meniscus. Neither will it

This combination of application advantages is instrumental in establishing parylene’s overall superiority compared to such liquid coatings as acrylic, epoxy, silicone and urethane. Nevertheless, parylene films are confronted by several failure mechanisms that need to be managed if coating processes are to be successfully implemented.

Issues that Complicate Parylene Coating

Contaminants: A clean surface is necessary to assure successful application and performance of parylene films. Contaminated surfaces do not support adhesion and are conducive to delamination. Visually undetectable ionic contaminants are capable of short-circuiting the assembly beneath the conformal film, as well as instigating corrosion that can damage the parylene coating. Most ionic contaminants can be removed by cleansing with purified water. Nonionic contaminants are visible along the assembly’s surface prior to parylene application. Because their presence attracts debris and foreign matter, they limit parylene adherence, causing pealing, cracking or other performance dysfunction. They're generally organic compounds like greases, oils or hand lotion, although rosin and silicone are also non-ionic. They generally can be removed with solvents and surfactants.

Delamination: Proper adhesion of parylene to the substrate surface is critical to its role as a conformal coating. One problem can be parylene’s underlying chemical structure, which can interfere with dependable surface interface, constraining adhesion with some materials. The resulting delamination separates the conformal coating from the substrate, producing a poor, unacceptable finish characterized by torn, unattached, and non-conformal coating. Even where surface exposure is incomplete, uncovering even some segment of the assembly negates the objective of conformal coating. Removal of masking materials, materials incompatibility, or unclean substrate surfaces may instigate delamination and subsequent lack of parylene adhesion. Appropriate coordination between the grade of parylene coating and the substrate material generates reliable adhesion and lamination. In these cases, altering either the coating type or modifying the surface energy better assures adherence. Working with a parylene type maintaining materials’ compatibility with the substrate and displaying applicable moisture impermeability is important, as is surface cleanliness. The objective is transforming the interaction of surface energies so they better support adhesion.

Limited throughput: The parylene manufacturing process is valuable because of: 1) the quality of coatings it generates and 2) it is exceptionally controllable and repeatable, delivering extremely consistent results from batch-to-batch. However, CVD is also time- consuming and generally confined to small-batch production, which can vary between 8 – 24 hours, despite smaller batch-size. Deposition chambers are somewhat costly and tend to be physically small, reducing total quantity of product coated during any single coating session. Extreme coordination between the coating service’s work schedule and that of its customers is essential to limit production/delivery delays.

Masking/prep: Although directed to targeted assembly areas by the CVD process, gaseous parylene can spread to non-targeted parts of the substrate. Assuring coating does not adhere to inappropriate sections can require labor intensive masking and preparation that further retard completion of production procedures.

Outgassing: The gaseous emission from a processed layer of coating film exposed to either heat or reduced air pressure, or both. Fortunately, Parylene has very low levels of outgassing.

Solder joint defects: Depending on their properties and application processes, conformal coatings can increase assembly solder joint fatigue; parylene can increase solder joint fatigue by about a factor of three, if improperly applied to the component.

Tin whiskers: The growth of spikey, whisker-like protrusions along the surfaces of metal components, believed to be encouraged by mechanically and thermally-induced stresses. Responsible for assembly arcing and short-circuits. Although parylene is very effective in limiting tin whisker growth, the condition can develop if film application is inadequate.

Weak metal adhesion: Parylene adhesion to noble metals such gold, silver or stainless steel is poor. This is a problem, for example, because gold’s superior conductivity properties make it a common element in many of today’s PCBs. Although several methods of adhesion promotion can significantly enhance parylene’s metal adhesion, they generally increase costs substantially because they are either labor-intensive or require specialized materials to generate desired product outcomes.

Summary

Parylene’s overall superiority as a conformal coating is verified by both the literature and practical application. However, its performance efficiency can be critically effected by the conditions discussed above. Proper parylene type and application of coating thicknesses appropriate to the particular assembly, its materials and uses, can significantly eliminate these problems.

Points to Consider

Designers must keep costs in mind when designing a project.

In the world of conformal coating, that means finding ways to get the best protection for your device at the lowest cost.

Knowing that, if you’re working on a Parylene project, it’s important to fully understand the 5 elements that go into Parylene pricing. Approaching each area correctly will help you achieve the lowest possible cost for your project:

Labor Costs for Parylene

In many cases, the biggest cost of a coating project is manual labor. Tasks such as cleaning, masking, and inspection take time. They must also be performed by a well-trained technician.

There are two ways to minimize your labor costs.

First, the old saying, "measure twice, cut once" applies with a Parylene coating project. Mistakes in the planning stage can often lead to costly, time-consuming repairs. It's important that you clearly document exactly what you want to happen. The last thing you want is a communication error that leads to a problem during the application process.

Second, ensure you have competent, well-trained technicians working on the project. Mistakes with Parylene lead to time-consuming, expensive repair work. This repair work can often be the single biggest unexpected cost for a Parylene coating project.

Raw Material Costs for Parylene

Parylene dimer is the raw, solid form of Parylene. During the application process, the dimer will be vaporized and then pulled into a vacuum chamber. The gas molecules will deposit evenly on any object inside the chamber, creating a thin, protective Parylene layer on the objects.

Some Parylene dimer types cost as low as $200 per pound. There are also specialized forms of Parylene that can be as expensive as $5,000 a pound.

To minimize material costs, consult with a Parylene expert as early as you can in your design process. By working with an expert, you can be sure you're not paying for specialized materials unless you actually need them.

Adhesion for Parylene

Parylene can coat almost anything.

Its unique features allow it to be used effectively on a diverse range of materials, including metal, ceramic, paper, plastic, ferrite, resin and silicon.

Parylene can be made to conform to any shape, including sharp edges, crevices, points, flat and exposed internal surfaces. Parylene works under pressures, stresses and in environments that would be detrimental to other types of coatings.

Despite Parylene’s versatility, some materials will still need a bit of preparation to ensure the Parylene properly adheres to the device being coated. The most common surface modification method to improve parylene adhesion is the use of A-174 silane.

A-174 silane is usually applied after the masking operation. Technicians will apply the material either by a manual spray, soaking, or a vapor phase silane process. The silane molecules form a chemical bond with the surface of the device. This, in turn, provides a surface Parylene can easily adhere to.

The way to minimize adhesion costs is to prepare the device correctly the first time. Poor adhesion due to poor device preparation can be another cause for expensive rework and repair.

Parylene Lot Sizes

The vacuum chambers used for Parylene coating have a fixed size. This means one batch of Parylene can only coat as many items as can fit in a single chamber. The chambers we use at Diamond-MT range from 11" by 11" up to 16" by 31", although larger chambers do exist.

To optimize costs, work with your coating provider to get as many items inside the deposition chamber as possible at a given time.

Time to Complete a Parylene Batch Run

One "run" of Parylene takes anywhere from a few hours to over a day. However, the preparation for a Parylene coating project begins weeks or months before the application.

Most coating providers will have a standard, explicit set of processes they use for customer orders. For the best results and lowest costs, let the providers use their standard process with your devices.

If you ask for a rush on a project, you risk introducing errors. Your coating provider might also charge a rush fee for orders on a tight timeline.

The No. 1 Thing You Can Do to Prevent Runaway Costs in Parylene Coating

The No. 1 way to keep your costs in line when carrying out a Parylene coating project is to avoid mistakes in the first place. The importance of properly preparing your device for Parylene coating success cannot be stressed enough.

As always, the most effective way to prevent coating failures is to ensure you’re working with an experienced coating provider.

Experienced technicians will know how to apply a wide variety of coatings, without causing any of the problems we’ve discussed in this article. And they’ll know how to complete your project at the best possible cost for you and for your company.

Key Areas of Concern

Parylene application typically generates an ultra-thin layer of electrical insulation that prevents contact between physical contaminants and the conductive elements of printed circuit boards (PCBs). Parylene also protects PCBs from the impact of corrosive vapors and moisture that may degrade their metallic components, providing a reliable barrier that significantly retards the impact of these contaminants.

Parylene is differentiated from competing conformal coatings – acrylic, epoxy, silicone and urethane – by its application process. Whereas the other conformal coatings employ some kind of wet application method – brushing, dipping or spraying are common methods -- parylene’s chemical vapor deposition (CVD) process has no intermediate liquid phase. Beginning in a powdered state, the parylene is converted to a gas through cross-link polymerization at the molecular level; there is no intermediate liquid phase. The resultant vapor penetrates deep with the substrate surface to provide absolutely conformal coating that typically surpasses the performance of wet coatings on most functional levels.

While its distinctive deposition technique generates the majority of parylene’s functional advantages compared to competing coating materials, it can also be the source of parylene failure. In all cases, proper application is essential to assure parylene’s optimal performance. Otherwise, problems may emerge due to failure of the parylene film.

Five Sources of Parylene Failure

Inappropriate parylene application can result when contaminants such as stray particles, oil, metal shavings, dust, and dirt remain on assemblies during the deposition process. These disrupt parylene penetration of substrate surfaces and the creation of the uniform, pinhole-free coatings that are its best-known quality. The consequent weakened parylene film-to-surface bond, can lead to such causes of parylene failure as (1) bubbles, moisture diffusion and pinholes, (2) corrosion, (3) cracking, (4) delamination, and (5) problems from substrate outgassing.

Conclusion

Because of vulnerability to contaminants, cleaning the surface of the substrate prior to coating is crucial to achieving parylene adhesion. Trace contaminants disrupt the bond between parylene film and underlying surfaces. Not always immediately apparent, compromised adhesion will eventually compromise the coating and, ultimately, the end product, thus neutralizing parylene’s protective benefits.

Parylene Explained

Although parylene (XY) is a well-recognized and often used conformal coating, misconceptions about what it is and can do are common. These mistaken beliefs interfere with true understanding of parylene’s uses. Five of the most consistent misconceptions – and appropriate corrective information – should clear things up.

Parylene Is Too Expensive for Normal Use

Compared to liquid coatings, parylene’s higher processing cost is no misconception.

However, these costs can be made more affordable. While dimer is expensive, XY coatings frequently are effective at thicknesses measured at the micron/nano level, rather than in millimeters, lowering material costs. Parylene’s more dependable performance, relative to liquid coatings, means fewer operational problems and less assembly failure, an important cost consideration whether XY films are used for medical implants, aerospace technology or weapons’ systems. Parylene’s performance reliability and exceptional operational versatility for critical devices cannot only be life-saving, but also cost-saving, despite initial higher price during production. Dimer and process costs are high, but their appropriate selection leads to longer-lasting, better coating quality and more reliable performance, XY’s best recognized and respected characteristics.

Every XY Type is the Same

Parylene dimer comes in two primary types -- C and N formulations, but other types -- D, F and AF-4 – are available; each has a specified utility distinguished by different electrical and physical properties. The most popular type -- C -- offers better performance across most metrics, generating exceptional protection from corrosive gases, due to low chemical, moisture, and vapor permeability. Depositing quickly on most substrate surfaces, C’s lesser throw-capability can reduce crevice-penetration activity. Among Parylene N’s key advantages are:

Parylene D withstands temperatures as high as 125°C, but lacks sufficient biocompatibility for wide use in medical devices. Very durable, D provides reliable film protection at 134°C, for 100,000 hours, through persistent exposure to 100°C in atmospheres dominated by oxygen. Type F parylene offers good throw-capability and crevice penetration. Slower deposition limits its uses, impeding current commercial uses. Due to higher oxidative resistance and UV stability than other XY types, AF-4 reliably protects outdoor assemblies from pollutants, salt and water.

Parylene Noodling is a Defect

Before CVD, XY is configured as a covalently-fused, monomer-based linear chain that resemble strands of pre-cooked spaghetti-like noodles, when viewed microscopically. Held together by chemical cross-lengths, they may be elongated, but are never clustered together or precisely straight, ranging between a few nanometers to several tens-of-nanometers in length. This basic alignment of parylene’s physical structure is its standard morphology. In this format, noodles are NOT a defect, but characteristic of XY’s normative shape and a source of the applied coating’s strength. However, defective noodling can occur through inadequate application or deposition onto a surface unprepared for adhesion:

This noodling is deficient, assuming a random shape, rejecting parylene’s typical pinhole-free uniformity. Disordered adhesion is the outcome, compromising the conformal film’s structural integrity and adhesion. As an integral structural XY-component, you can’t avoid the presence of parylene noodles, but you can control them.

De-wetting is a prominent parylene post-application problem.

De-wetting is a major failure mechanism of liquid coatings, disrupting their protective conformal protection. It occurs when coating material does not wet substrate surfaces upon application, causing deterioration of the conformal film. Solder also fails to adhere to components. In contrast, parylene is NOT pre-synthesized or dispensed during application in a wet format. No wet processes/liquid materials are used. Applied by CVD rather than the wet methods used by liquid coatings, XY is converted from a solid to a gas, with no wet stage. CVD’s free radical polymerization technique forms resonance-stabilized XY diradicals that penetrate substrates, entering and filling pores/voids under and above the targeted surface. Directly-synthesized in one-step processing, CVD sequencing bypass de-wetting, freeing XY of this coating defect.

Parylene Has Poor Metal Adhesion.

As with parylene cost and noodling, this is not entirely a mistaken belief. Relying on mechanical adhesion, XY doesn’t actually adhere to the surfaces it coats; rather it sticks to itself, filling in the space surrounding the targeted surface, securing existing cracks, pits or other imperfections. Metal surfaces have far fewer of these surface defects; their material smoothness leaves XY less of a substantive base of coating adherence. This is especially true for noble metals, noted for their excellent conductivity -- gold, silver, or platinum are capable of resisting acid attack, chemical action and corrosion, making them valuable components for many assemblies. Treating the noble metal surface with the compound A-174 silane improves XY adherence, making it viable for metal coating. Easy to apply, silane can be:

Silane treatment assures effective parylene adhesion to metal substrate components, negating this misconception.

Points to Consider

The parylenes consist of a range of para-xylylene polymers whose desirable physical and electrical properties support expansive utilization as conformal coatings for electronic and medical devices Parylene films are applied to substrates via a chemical vapor deposition (CVD) process, which deposits monomeric parylene vapor homogeneously and deeply into the surface of printed circuit boards (PCBs) and related assemblies/components.

In comparison to liquid conformal coatings – acrylic, epoxy, silicone or urethane -- parylene offers highly desirable physical and electrical properties, performing where wet coatings might be compromised or insufficient. Among parylene’s many advantages are:

Despite these advantages, the application of parylene film to PCBs is complicated by several failure mechanisms that require adroit management to assure successful implementation of the CVD procedure. One of the most important is supervision of the batch process, wherein designated consignments of PCBs and other products undergo parylene application in the deposition chamber.

Batch Processing as a Production System

Typically, batch process production manufactures goods in sequential stages, that are in line but disconnected for performances at different workstations. Each lot of products – in this case PCBs, medical devices or other related items – comprises a batch coated by parylene CVD. Normally, batch process workstations are situated closeby in a manufacturing facility; for parylene coating, a vacuum chamber is used for each coating batch, with processes following a progression that leads to a final stage, deposition of the coating.

Implemented in a closed-system vacuum subjected to persistent negative pressure, the Parylene process integrates the following steps as part of the batch coating process:

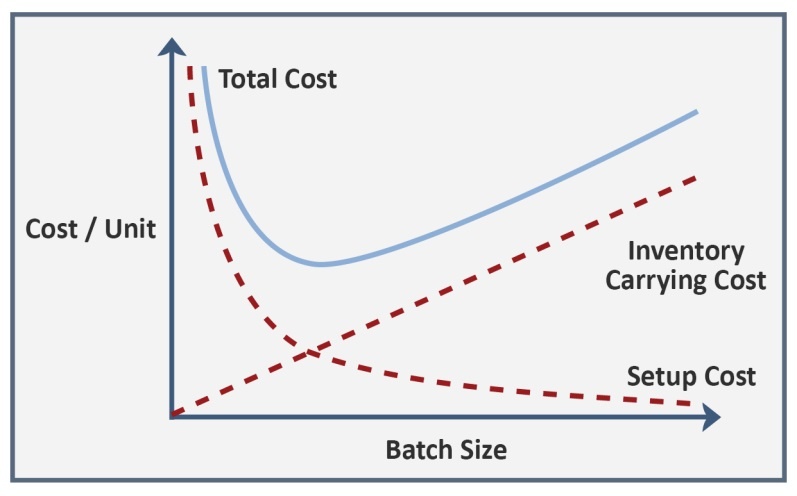

Chambers are typically small, which can limit batch size. The flexibility of batch processing supports just-in-time (JIT) manufacturing. Lean JIT batch-runs respond specifically to customer demands, largely eliminating outsized product inventories, while reducing waste in manufacturing/warehousing procedures. With parylene dimer materials costing between $200.00 - $10,000.00 per pound, and the need for worker interaction throughout production, a major consideration in managing CVD is the minimization of wasted resources and effort.

Aspects of Parylene Batch Processing

As described above, parylene batch coating procedures differ appreciably from conventional production line operations. Composed of a succession of substrate pre-treatment stages, coating processes are documented through a formal control plan that specifies batch size; methodical logistics for implementing the batch coating require controlled staging to generate both production efficiency and cost-effective coating operations.

The batch coating process requires structured handling and defined time periods. Regarding chamber load, if the same parylene type is used and the coating specifications are equivalent, the actual amount of time the product to-be-coated undergoes parylene deposition varies very little, when comparing small to larger batches. In general, time-consuming CVD is confined to small-batch production, which can vary between 8 – 24 hours, despite smaller batch-size.

Thus, a greater quantity of product in the deposition chamber for coating generally leads to a more economical batch coating process. However, CVD technology has built-in limitations that negate further reduction of chamber time, regardless of batch size. Therefore, real-time coordination between production and quality control processes must be rigorously synchronized to minimize wasted time and resources, while maintaining client specifications, consistently between orders. To this end, the parylene CVD process is effective because of:

Yet, these factors do not much diminish the generally limited throughput of parylene batch processing. Time-consuming CVD reduces operational efficiency, particularly with small-batch production dominating most coating assignments. Deposition chambers are somewhat costly and tend to be physically small, reducing total quantity of product coated during any single coating session. Turnaround-time required to complete coating assignments places further constraints on batch-size, a condition that cannot be overstepped since processes must be fully completed to assure successful coating application. Unused chamber volume reduces cost efficiency, so closely matching the batch size to the chamber capacity contributes to cost effectiveness. Diamond maintains both larger and small chambered coating machines to better optimize customer/company expense on coating assignments.