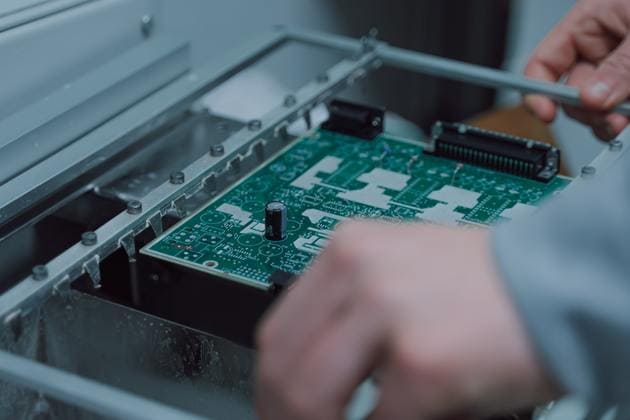

Many electronics manufacturers and leaders in similar industries understand the value of conformal coating and want to add coating application to their in-house processes. However, there are many steps involved in applying a coating, so it is easy to miss something crucial without the proper instruction.

The turnkey conformal coating consulting services at Diamond MT help your business set up a streamlined operation to apply coatings yourself.

There are many standards to follow if you want to set up your own coating application line:

With our training, Diamond MT will help your business establish a functional conformal coating production and application system in your facility. We will help you ensure your operation meets all laws and regulations and works productively to generate maximum profit.

Our consulting service gives you access to our extensive industry knowledge, which you can use to resolve issues with your coating's reliability and cleanliness. Our solutions save your company time and money by addressing your problems quickly and effectively.

Diamond MT consultation involves:

The advantages of partnering with Diamond MT for our parylene consulting services include:

Diamond MT is the industry expert for conformal coating preparation, application and curing, and our coating training and consulting services provide exclusive access to our unmatched expertise. Contact us for more information or request a quote online today.