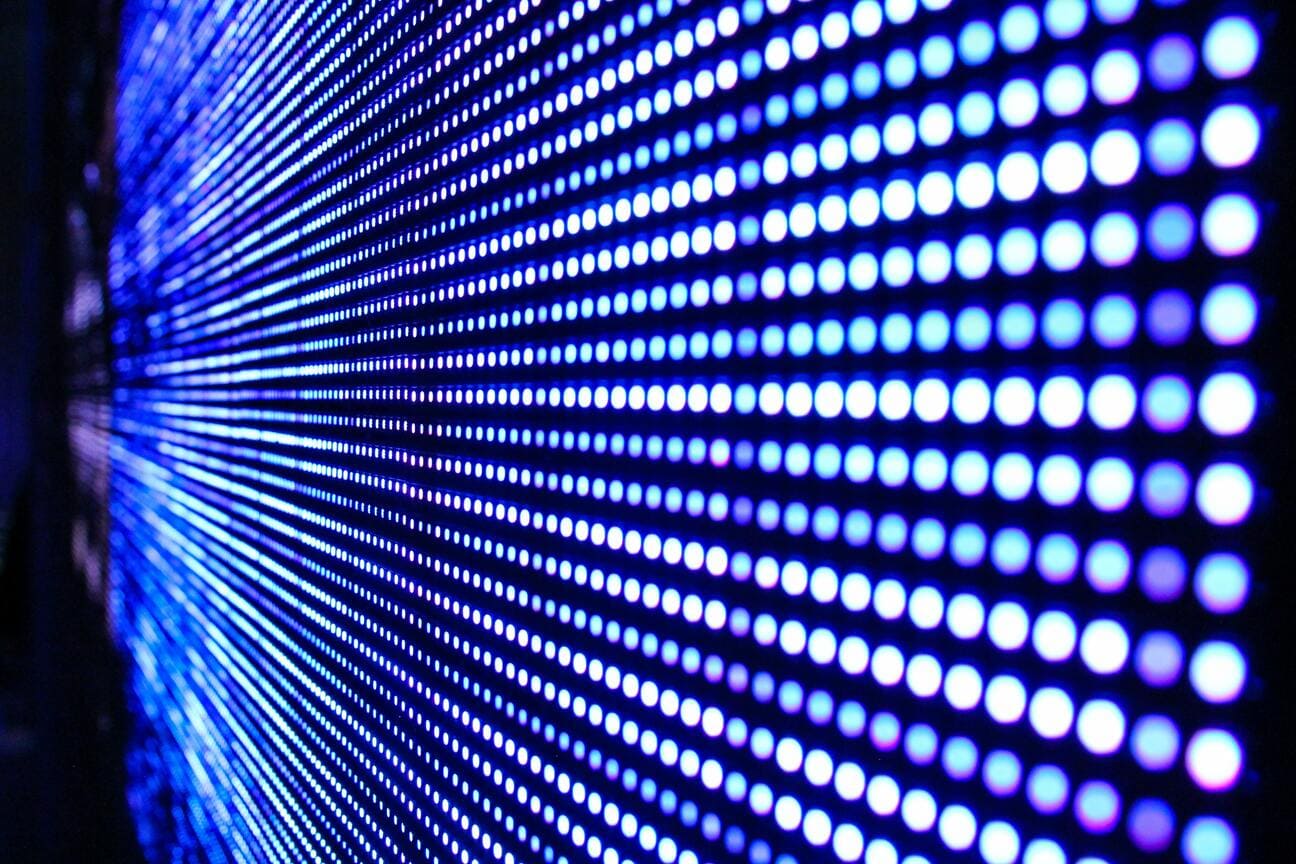

Light-emitting diodes (LEDs) are an integral part of electronics and are used in many industries because they are energy-efficient and adaptable. While LED lights have a 100,000-hour lifespan, harmful environmental factors can impact their durability. Because so many devices rely on LEDs, they need protection to work correctly.

Conformal coatings offer effective protection and do not inhibit the LED's function while preventing contamination. At Diamond-MT, we have conformal coating for video displays, vehicle lighting and similar components that use LED lights.

There are three coatings that can be used on LEDs:

Of these three options, parylene is the top choice. LEDs in a printed circuit board (PCB) for an outdoor application face tough operational and environmental conditions. Parylene is the conformal coating type that provides the best defense against ultraviolet (UV) light, moisture, chemicals and corrosion.

Other advantages of parylene for lighting include:

Many devices need LED conformal coating, including:

Our LED coating services include:

Since 2001, Diamond-MT has been the leader in conformal coating for LEDs. Our facilities meet International Standardization for Organization (ISO) 9001:2015 and Aerospace Standard (AS) 9100D standards for production. We can complete orders at the industry-leading rate of two to five business days. Our technicians follow various industry standards for the best coating on each device.

If you are looking for conformal coating for LEDs, the experts at Diamond-MT have the quality coatings and excellent service your project needs. Contact us to learn more about our conformal coating for lighting or request a quote for your project today.